Palsgaard’s pellet line expansion supports growing demand for food-grade plant-based polymer additives

Press release

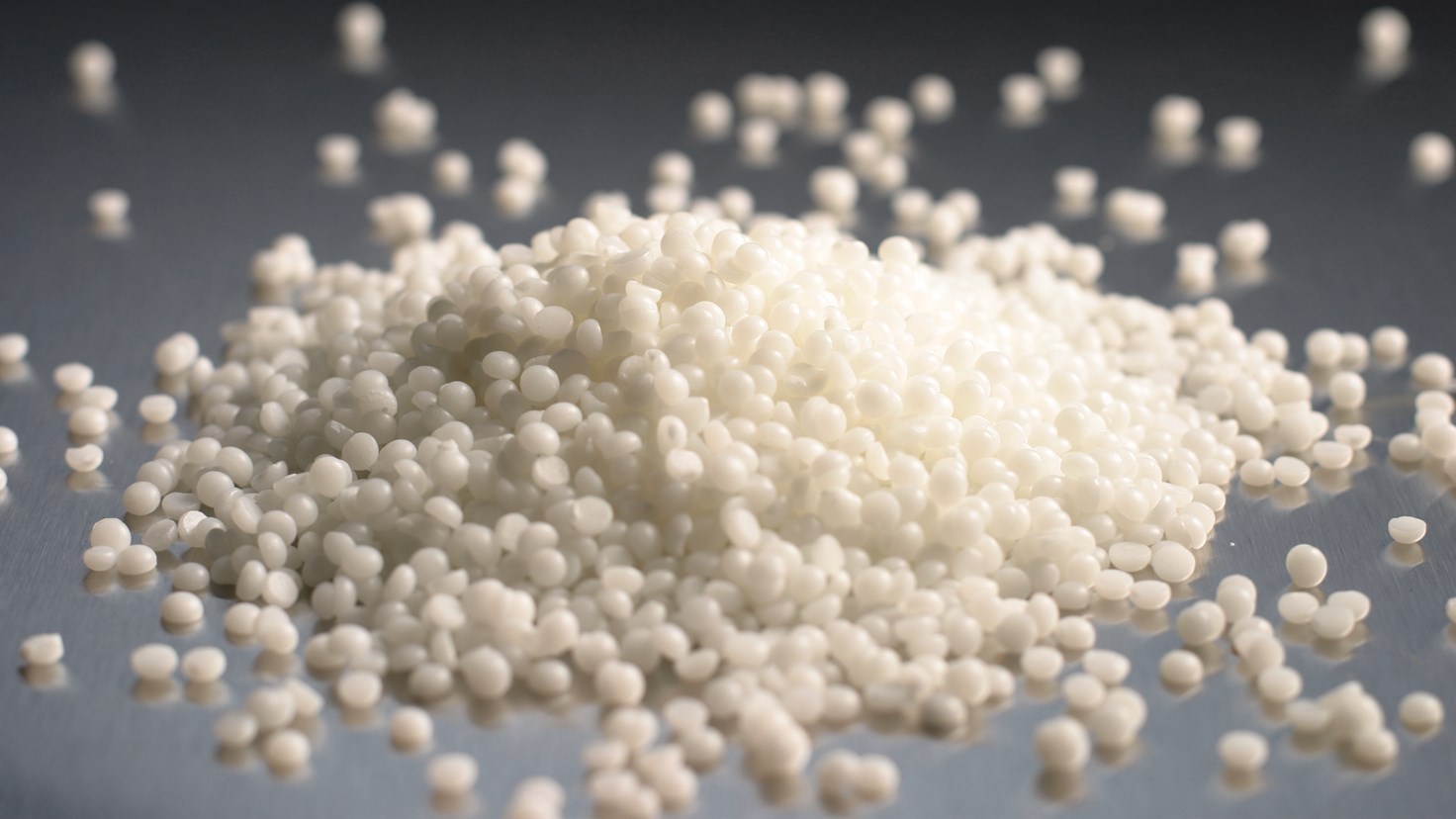

Palsgaard A/S is driving the trend towards more natural ingredients and additives as industries strive for enhanced sustainability by increasing the use of renewables in their materials sourcing. The Danish pioneer in food emulsifiers has opened a new 10,000 tonnes pellet line that also expands the manufacturer’s production capacity for Einar® brand plant-based polymer additives.

“We are seeing a fast-growing demand among consumers, brand owners, packaging designers and plastics manufacturers for more natural materials to reduce fossil depletion and waste,” says Ulrik Aunskjær, Global Industry Director Non-Food Business Development, Polymer Additives for Palsgaard. “Our expanded production capacity meets these requirements by boosting the availability of food-grade plant-based surfactants and modifiers for polymer manufacturers and compounders.”

The expansion of the pellet line also addresses the needs of compounders and processors who may wish to add specific Einar® products to polymers directly rather than as part of a more complex masterbatch formulation. This applies in particular to the use of Einar® anti-static additives for food and other packaging applications, where the availability of pelletised products enables a clean and straightforward process.

Palsgaard offers its Einar® plant-based anti-fog and anti-static additives in several grades tailored to film, injection moulding, foam and coating processes for a wide range of different polymers, from polyolefins and PVC to PET and engineering plastics. Moreover, the Einar® portfolio also includes slip additives, ageing modifiers, mould release agents, and dispersing aids. All products have full FDA and EU food-contact approvals.

In addition to the new pellet line, Palsgaard is investing in an advanced spray cooling tower that will raise the company’s spray capacity by at least 30,000 tonnes. The tower is scheduled for commissioning in early 2023 and will be supported by multiple new reaction, distillation, and esterification plants – all set to double the production capacity at the manufacturer’s Danish facility in Juelsminde by 2024. In total Palsgaard expects to invest 750 million Danish Kroner (100 million €) in the expanded capacities which, in line with the company’s commitment to sustainability, will not compromise Palsgaard’s carbon-neutral status.

Ulrik Aunskjær added: “We have a number of new initiatives, including establishing a solar park and a biogas facility, which will provide the necessary power and waste management infrastructure to enable the new production capacity to also be carbon neutral. This aspect was a very important consideration in the planning process for the new investment.”

About Palsgaard A/S

Palsgaard is a world leader in plant-based emulsifiers and polymer additives for the global food, packaging, and plastics industries. Since its founder Einar Viggo Schou invented the modern plant-based food emulsifier in 1917, the company has provided advanced industry know-how and innovation to an increasingly diversified customer base. From application centres around the world, Palsgaard’s experienced technologists support brand owners and manufacturers in optimising their sustainability by the use of natural, renewable ingredients and additives to mitigate their carbon footprint.

Palsgaard helps manufacturers grow and protect their brands by meeting consumer and regulatory demands for greater responsibility. The company is currently the world’s only commercial source of fully sustainable emulsifiers and additives based on RSPO SG-certified palm oil as well as rapeseed, sunflower, and other vegetable oils. All products are non-GMO, have full EU and FDA food contact approvals, and also meet halal and kosher requirements.

The company’s food emulsifiers and emulsifier/stabiliser systems have a long history of adding to the quality and shelf-life of bakery, confectionery, condiments, dairy, ice cream, and margarine products. At the same time, they can significantly improve the taste, mouthfeel, and texture while using fewer resources. Palsgaard’s plant-based polymer additives, including anti-fog and anti-static formulations for food and other packaging, build on this expertise and are rapidly emerging as highly effective and sustainable alternatives to conventional petrol-based additives.

Palsgaard, with headquarters in Juelsminde, Denmark, is owned by the Schou Foundation and has 588 employees across 17 countries. The company operates plants, sales offices, and warehouses across four continents. All of their six production sites in Denmark, the Netherlands, Mexico, Brazil, China, and Malaysia are carbon-neutral. In 2020, Palsgaard achieved a turnover of USD 218 million (DKK 1.5 billion) with products sold to customers worldwide in more than 120 countries.

For more information please contact:

Mette Dal Steffensen, Senior Marketing Specialist, Palsgaard A/S

[email protected] | +45 2073 4534