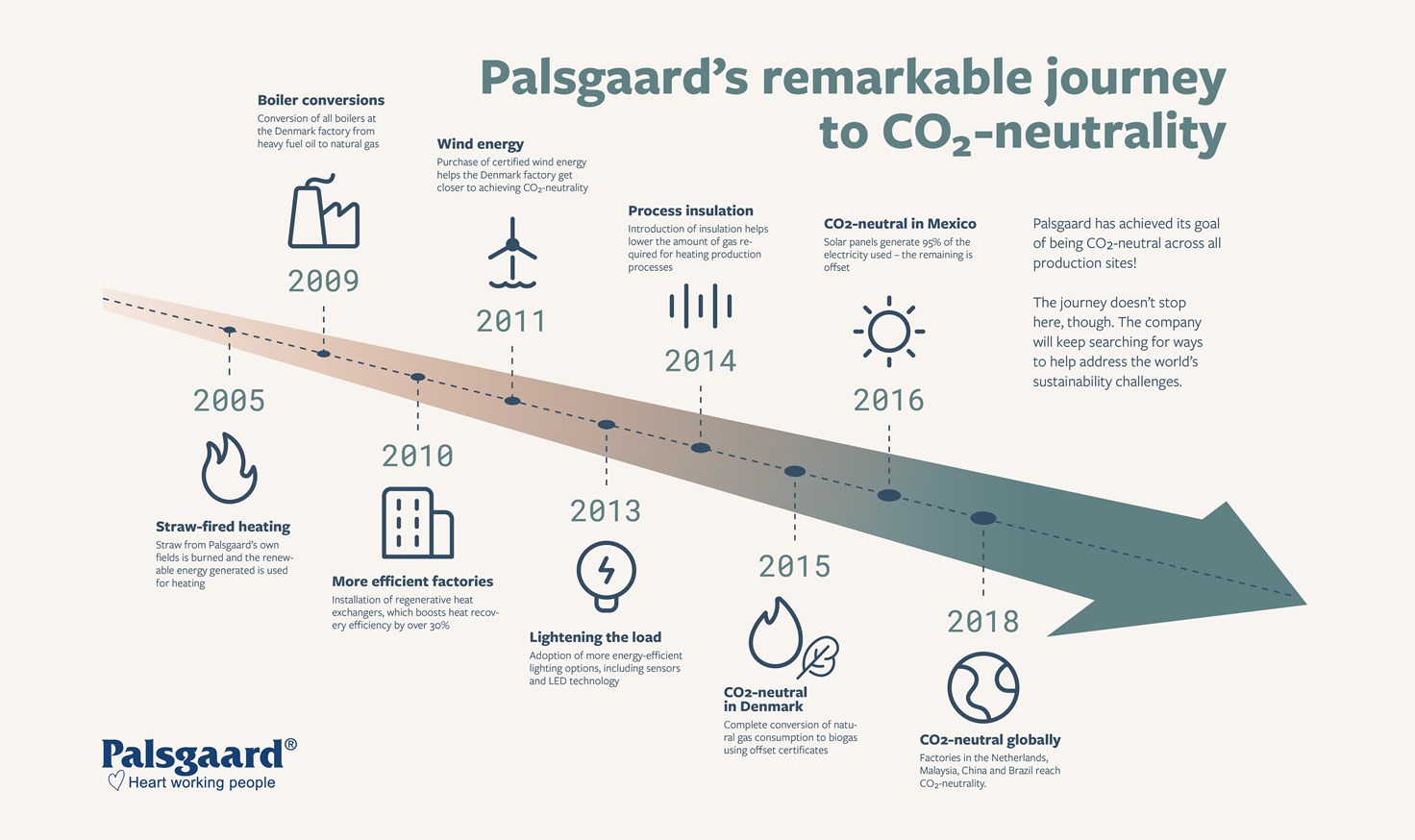

Not so in Denmark at the company’s headquarters in Juelsminde. The site was a natural starting point for reducing emissions on a greater level, also because it was using the most energy at the time. Some major changes had already been implemented before 2010, such as straw-fired central heating and industrial boilers conversion from heavy fuel oil to natural gas. With heat exchangers for process heat recovery, certified wind energy, low-energy lighting and process insulation, the factory set the pace for all other sites and became carbon neutral in 2015. The annual emission reduction amounts to 16,000 tonnes of CO2 or the equivalent of 4,200 households.

The second site to become carbon neutral was San Luis Potosí in Mexico in 2016, followed by Zierikzee in The Netherlands. At both locations, Palsgaard had made significant investments to upgrade the sustainable energy infrastructure, including the installation of hundreds of solar panels. In addition, the company purchased carbon offsets to compensate for its remaining CO2 emissions from liquefied petroleum gas consumption and electricity obtained from non-renewable sources. In contrast, the continued use of fossil fuels at the Dutch factory would have resulted in 1,300 tonnes of CO2 emissions per year – the same as produced by 165 Dutch households. Today, the plant is running solely on renewable energy. At San Luis Potosí, the achievement has put Palsgaard far ahead of the Mexican national target of 35% clean energy by 2024.

These milestones were then completed by the plants at Marechal Cândido Rondon (Brazil), Shanghai China) and Nusajaya (Malaysia) in 2018. Achieving carbon neutrality in Malaysia presented a major obstacle since the infrastructure for renewable energy and biogas in the country was not substantial enough to ensure reliable power production on-site. For this reason, Palsgaard has been purchasing CO2 offsets from the United Nations Carbon Offset Platform, which is governed by the United Nations Framework Convention on Climate Change (UNFCCC). The UNFCCC initiative offers UN certified emission reductions (CERs) that contribute to climate-related projects in developing countries. With this offset solution, the company’s CERs help fund two wind energy projects in India.

Jakob Thøisen comments: “All these accomplishments took ‘heart’ work from our people and a focus on innovation, keeping our eyes on the goal in line with our Corporate Social Responsibility.”